Barite is a mineral made up of barium sulphate. It has a high specific gravity of 4.5 which is exceptional for non-metallic minerals which makes it suitable for a wide range of industrial, medical, and manufacturing uses.

Barite is mainly used in the oil and gas industry as a weighing agent in drilling fluids. The rising production of oil and gas around the globe, coupled with increasing penetration of barite in drilling fluids, are key factors boosting the market.

Worldwide, 69 – 77 per cent of barite is used as a weighting agent for drilling fluids in oil and gas exploration to suppress high formation pressures and prevent blowouts.

. Its global production in 2017 was estimated at 9.5 million tonnes. China has the highest production estimated at approximately 43 per cent of global production and consuming 19 per cent of its total production.

Morocco is next after China in terms of barite production, then India and the USA, while Nigeria is the twentieth. USA consumes approximately 25 per cent of global production.

In view of high application in the oil and gas industry, the global barite market size was $1.55 billion in 2019. This is expected to increase at a compound annual growth rate (CAGR) of 3.8 per cent from 2020 to 2027.

Although, the outbreak of the COVID-19 pandemic in 2020 affected its demand as oil producers were crippled with excess supply and diminishing demand, the global oil and gas industry is expected to recover from 2022 and grow at a moderate pace till 2029, thereby necessitating a steady deployment of rigs, particularly in offshore fields. This is expected to drive the demand for drilling fluids, thereby creating a lucrative platform for market growth.

Barite is abundantly available in Nigeria; however, it is mostly processed using non-conventional methods.

According to the Department of Petroleum Resources (DPR), Nigeria has a reserve estimate of 21,123,919 MT of barite. The states which possess barite are popularly known as Benue troughs. These are Nasarawa, Plateau, Taraba, Adamawa, Benue, Plateau, Cross River, Ebonyi and Gombe states. The deposits of barite in Nasarawa State are estimated to be 730,000 tonnes. Also, over 7.5million tonnes have been reported in Cross River, Benue, Taraba, and Bauchi States.

Despite the abundant availability of barite in Nigeria, the country produces only 10,000 tonnes and consumes 23,000 tonnes, leaving a deficit of approximately 13,000 tonnes. As a result, Nigeria has had to rely on imported barite from China, the Netherlands, Morocco, Egypt and India.

Available statistics indicated that Nigeria imports 13,000 tonnes annually and with a tonne costing $230, this amounts to an annual expenditure of $29.9 million for barite importation.

In an exclusive chat with Science Nigeria, a mining expert, Mr Joseph Okpe, said some of the major challenges militating against barite production in Nigeria is underdevelopment of the mining sector. This, according to him, made the sector to contribute only a meagre 0.3 per cent to national GDP and the country to constantly depend on minerals importation from other countries.

He said barite is among the 34 mineral deposits identified in Nigeria. All ownership rights of mineral resources belong to the Federal Government and it reserves the power to grant permission to registered mining companies to explore, mine and sell mineral resources.

“The challenge which generally affects the mining of various mineral resources also affects the mining and beneficiation of barite in Nigeria. Some of the challenges the mining sector is facing is lack of investment in barite mining. There is need to involve the multinational corporations and small-scale mining companies that have been hitherto reluctant to invest in exploration and mining with appropriate incentives.

“Other important challenges are poor infrastructure such as inadequate electricity supply, unavailability of loans, low technological knowhow and lack of access roads to mining sites. Illegal mining is also a major constraint. There are several illegal mining activities in most areas where minerals are located. Most of these are influenced by foreigners that do not have the required licence to mine mineral resources. Consequently, the resources meant for federal government are hijacked by foreigners or individuals. Another major impediment is the low grade of barite.

“Majority of barite ore with SG lower than 4.3 are dumped or considered as wastes or not mined at all. Consequently, due to low local production of barite, imported barite is usually blended with locally produced barite to meet the API SG requirement of 4.3.

“To obviate the problems associated with mining and beneficiation of barite in Nigeria, successive governments at the federal level have been making efforts towards improving the performance of the barite subsector. For instance, the Nigeria Content Act of 2010 campaigned for increase of local content in Nigeria’s oil and gas industry. The act stipulates that 60 per cent of barite utilisation in the country should be sourced locally,” he said.

It would be recalled that the Federal Ministry of Mines and Steel Development (MMSD) in 2016 developed a road map aimed at ensuring that Nigeria’s industrial minerals meet the standards of the manufacturing, and construction industry in order to reduce import dependency. The road map delineated seven key minerals for quick development of which barite is inclusive.

“To meet this objective, government has mapped out a development strategy to support, regulate and monitor stakeholders along the barite value chain. This is to assist local companies to meet the industry standards, develop capacity, and close the demand-supply gap that exists in the country in the short term. The long-term plan is to place a ban on importation of barite once the local market is satisfied and to export barite to other African countries where oil and gas drilling activities are taking place,” he added.

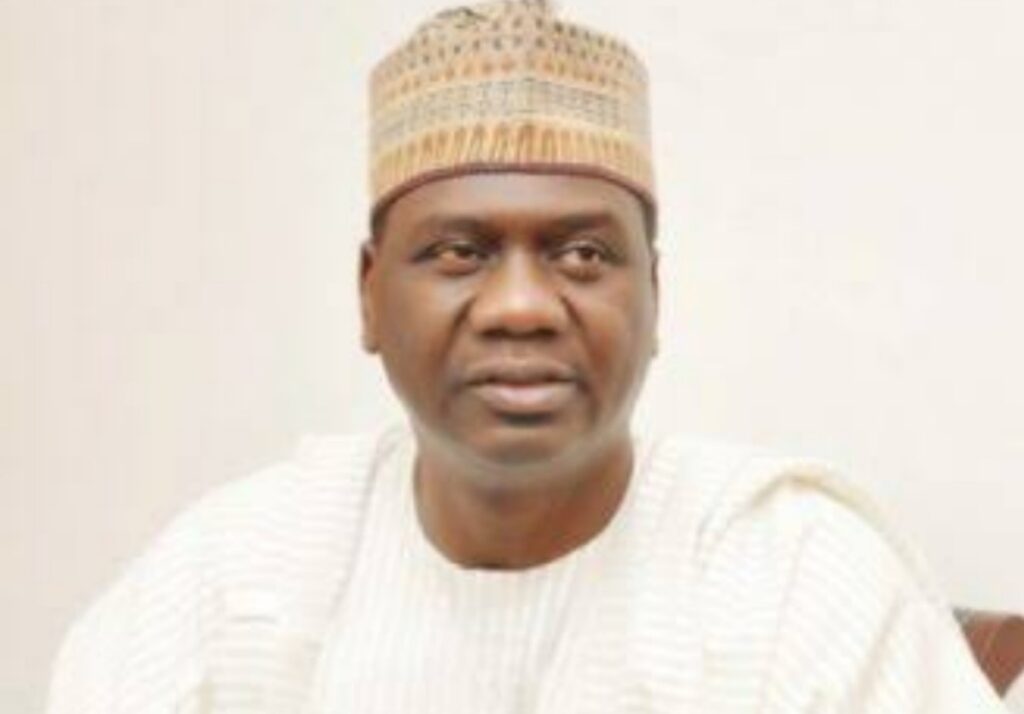

Speaking on barite development in Nigeria, the director-general of the Raw Materials Research and Development Council (RMRDC), Prof. Hussaini Doko Ibrahim, said Nigeria loses $29.9 million in capital flight on the importation of barite annually.

In an exclusive chat with Science Nigeria in Abuja, he described the development as no longer acceptable, saying the council had put in place plans and strategies to boost local production of barite in Nigeria in order to stem import dependency.

The RMRDC boss pointed out that the council had characterized samples of barites from most of the deposits in the country and that it was working on promoting the beneficiation of low-grade barite by using techniques such as gravity separation, floatation and magnetic separation techniques in collaboration with reputable equipment fabricators in the country.

The council, according to him, is also working to promote the upgrading of the low-grade barite to meet up with the API requirement for oil and gas drilling and the low-grade barite that does not meet API grade of 4.2 after beneficiation, he added, would be diverted to glass or paint production industries.

Ibrahim said the council in collaboration with stakeholders in the petroleum sector including the Petroleum Development Trust Fund (PDTF) and the University of Ibadan was working for the development of barite as drilling mud weighing agent.

“The project is looking at the impact of Nigerian barite and ilmenite on enhancing the drilling mud weight in oil and gas industry. The project aims at considering the feasibility of the utilization of local barite and ilmenite as weighing agents to enhance drilling muds. The investigation will ultimately provide quality and reliable geoscientific information that will encourage the use of locally available barite and ilmenite,” he said.

He further said the council in collaboration with experts was working on making these recommendations a reality as stakeholders had also observed the need to ban importation of barite in the country, adding they also observed the need for all actors in barite value chain development to come together to ensure utilization of locally mined barites and resuscitate the local mines already abandoned.

The RMRDC helmsman said the council as a member of the Technical Tariff Committee (TTC) would advocate an appropriate tariff regime that would give local production a competitive edge.

“In addition to the above, the council is establishing a mineral testing and certification centre at the African University of Science and Technology (AUST), Abuja. Miners can now be able to know the grade of their minerals before putting them in the market. This will enable them to charge appropriate prices for their commodities. The council has geared up activities to facilitate post COVID-19 era economic growth agenda of the government, promote wealth creation and to save the $29.9 million expended annually on barite importation,” he added.