Nigeria, despite being a major cassava producer, spends a significant amount of money each year importing sorbitol.

In 2019 alone, over $6.7 million worth of sorbitol was imported into the country, totalling about 12 million kilogrammes from countries such as Indonesia ($2,113.67, 3,978,190 kg), India ($1,916.43, 3,014,570 kg), Turkey ($1,260.35, 2,376,310 kg), China ($1,233.79, 2,421,100 kg) and the United States ($145.23, 259,394kg).

This importation of sorbitol costs the country approximately N40 billion annually. However, according to Volza’s 2022 Nigeria Import data, sorbitol product of category of HSN Code 29054400 was imported at a cost of USD 1.4K by 74 Nigeria Importers from 33 suppliers. By investing in domestic sorbitol production, Nigeria can potentially save billions of naira each year.

Cassava is a major crop produced in Nigeria and in 2018, the country produced 59.5 million tonnes of cassava, which represented 21 per cent of the world’s total. However, around 90 per cent of the cassava produced is consumed locally without any value addition.

Cassava can be grown throughout the year, making it a preferable crop to seasonal crops such as yam, beans, or peas. Additionally, cassava can adapt to climate change, resist drought conditions, pests, and diseases, and store its roots for extended periods. The use of fertilisers is limited, and it can be grown on fallow lands with harvesting of the roots varying from 6 months to 3 years. The government has been promoting self-sufficiency in cassava production, and the Presidential Initiative 2002 expects the cropped area of cassava cultivation to reach 5 million hectares with a projected annual yield of 150 million tonnes.

More recently, the concession on cassava biomass and bio-ethanol value chain development was approved by the Federal Executive Council. As disclosed by the Infrastructure Concession Regulatory Commission (ICRC), the concession aims to create wealth, provide jobs, reduce poverty, improve food security and nutrition, provide renewable energy, and reduce carbon footprint. The cassava bio-ethanol value chain is expected to generate a total of N105 billion within the five-year concession period. This is expected to be done on a pilot phase by building a bio-technology park on a 20-ha plot across 20 universities, academia and research and development institutions.

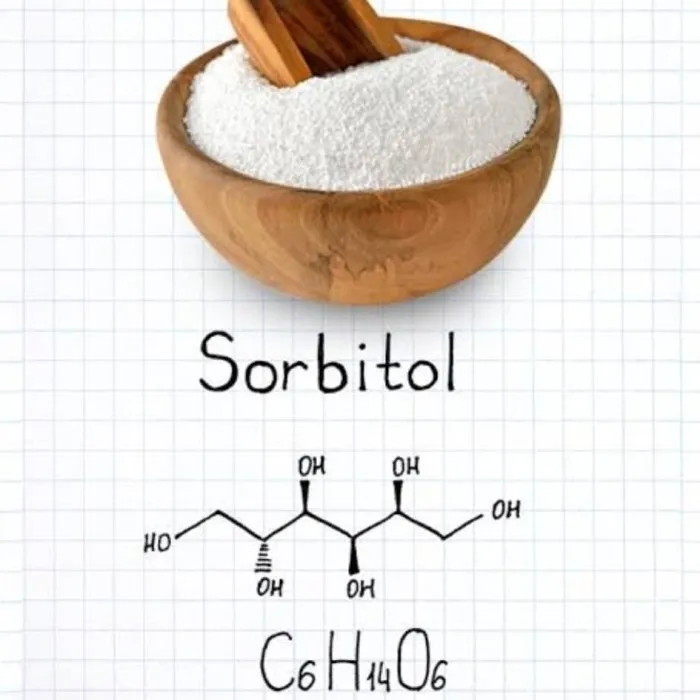

Sorbitol is a sugar alcohol with six-carbon atoms and six hydroxyl groups, and it occurs naturally in fruits such as apples, pears, peaches, apricots, and nectarines, dried fruits, and some vegetables. There are seven sugar alcohols approved globally for use in food products, including sorbitol (E420), mannitol (E421), isomalt (E953), maltitol (E965), lactitol (E966), xylitol (E967) and erythritol (E968). They are generally recognised as safe (GRAS).

Sorbitol is about 60 per cent as sweet as sucrose and has an average caloric value of 2.7 kcal/g compared to 4 kcal/g for sucrose. Sorbitol is highly hygroscopic, chemically inert and stable at high temperatures, and its safety profile is generally recognised by the World Health Organisation, the European Union and designated authorities of Australia, Canada, Japan and the U.S. Food and Drug Administration (FDA).

In an exclusive chat with Science Nigeria, the national vice president of All Farmers Association of Nigeria, Chief Daniel Okafor said Sorbitol (C6H14O6) is a sugar alcohol (polyol) with six-carbon atoms and six hydroxyl groups. Sorbitol occurs naturally in fruits such as apples, pears, peaches, apricots, and nectarines. Other natural sources include dried fruits like prunes, dates, and raisins and some vegetables. Sugar alcohol is a polymerised sugar with an alcohol functional group.

“Commercially, sorbitol is generally available and marketed in the form of a 70 per cent solution – a polyhydric alcohol with a colourless to faint yellowish appearance. Liquid sorbitol remains mostly inert to humidity fluctuations. The aqueous solution replicates many properties of glycols and glycerol, thus acting as a suitable possible substitute. Sorbitol liquid is also a good humectant and water stabiliser, which enables its utilisation in the gelatin capsule industry and cosmetic emulsions.

Sorbitol is produced at a commercial scale by the reduction of d-glucose from biomass in a high-pressure reactor using hydrogen gas in the presence of a catalyst. However, epimerisation of glucose in an alkaline medium into mannose can easily occur and subsequently be hydrogenated into mannitol. Therefore, a pH of 7.5 is mostly used for glucose conversion to avoid epimerisation. Although enzymatic production of sorbitol from Z. mobilis and Candida boidini has also been reported, glucose remains the best source of sorbitol production due to its availability and low cost. Starch-rich materials such as corn, wheat, potato, and cassava are used as raw material for the production of sorbitol,” he said.

Speaking on the efforts of the Raw Materials Research and Development Council, the council’s director-general, Prof. Hussiani Ibrahim, said these developments combined with RMRDC initiatives on cassava productivity boosting programs in collaboration with the National Root Crops Research Institute, Umudike, will further increase cassava output locally.

In view of this, it is imperative to expand the cassava value chain development to include the production of industrial raw materials that are in very high demand locally and also have competitive export potential. One of such product required by numerous manufacturing companies in the country is sorbitol. Although some companies produce it locally, the high industrial requirement necessitates its importation.

To stem this occurrence and place the country on an economically sound track, the council, in collaboration with stakeholders in research institutes and in the industry, has put in place plans to promote investment in sorbitol production from cassava. In view of this, the Council has designed and developed a process for the local production of sorbitol. A pilot plant with a production capacity of 75kg/batch has been installed at the RMRDC Technology and Innovation Complex.

The plant can produce both liquid/syrup and crystal/powder sorbitol products, which are locally required and also have high potential for export. The equipment has been tested, and the products compare favourably to international quality standards. The council is engaging stakeholders on establishing the plant in major cassava-producing ecologies in the country.

“The beauty of the investment is that it can be operated at small, medium and large scales. As a result, it is within the capacity and capability of local government areas, state governments and private sector investors in the country to key into the investment plan. This will enable the proliferation of production plants in the country.

“When this is achieved, this initiative will save the nation more than N40 billion annually in foreign exchange equivalent, apart from the export potential to generate foreign exchange. It will also promote job creation and poverty reduction in the country.

“According to the strategic plans put in place by the council and other stakeholders,” he added, “this is expected to grow geometrically within the next few years.”