The Raw Materials Research and Development Council (RMRDC) has said the council has saved the nation N5 billion of capital flight annually from the importation of technical grade talc through its interventions in the sector.

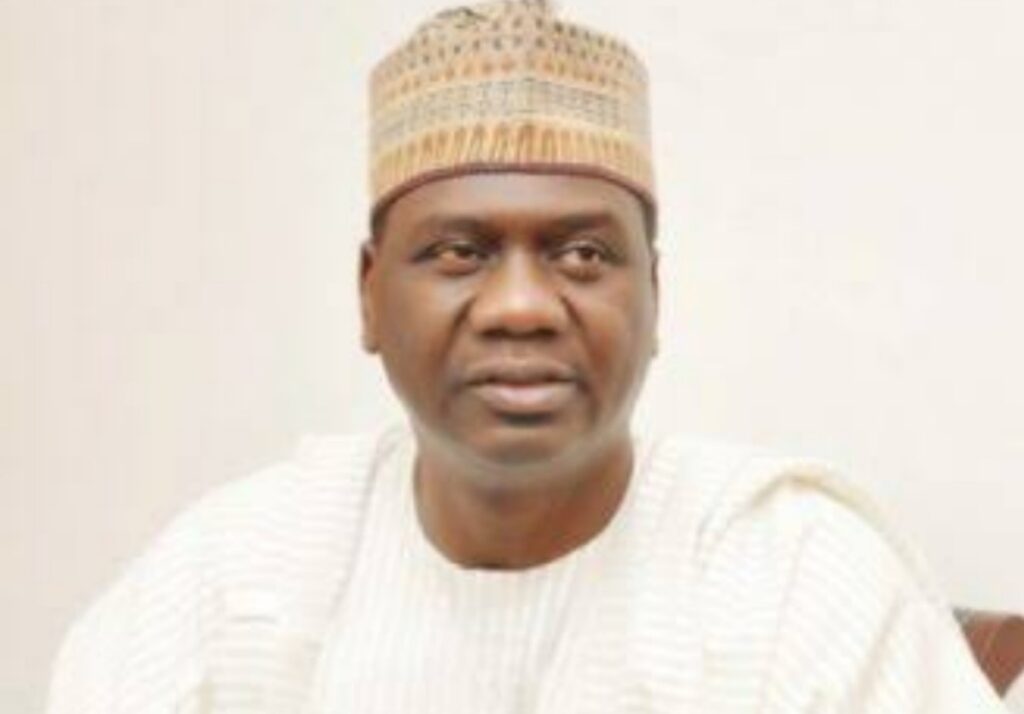

The director-general of the agency, Prof. Hussaini Ibrahim, made this known during an exclusive chat with Science Nigeria in Abuja, saying the council’s numerous initiatives to bridge the deficit in the sector had led to Nigeria being self-sufficient in technical grade talc.

He explained that talc is one of the basic clay minerals used in the production of ceramics which is abundant in Nigeria.

Currently, there are only 9 ceramic manufacturing companies at present in Nigeria with 8 of them manufacturing ceramic tiles, and one, ceramic sanitary ware. The combined capacity of the companies was 114 million m3 in 2018. As a result, there is about 11 million MT shortages in the demand and supply gap for ceramic products in the country which are cushioned by importation, he pointed out.

Statistics, according to him, show that the country imported ceramics products worth over $800 million in 2018 and $900 worth in 2019 respectively. The importation of the products into the country is expected to reach $2.1 billion by 2025. This is to be driven by rising demand, particularly in the real estate sector as the building and construction industry is the second fastest growing sector in Nigeria with a housing deficit of 17 million units. According to World Bank estimates, this would require about $22 billion to fund.

In view of the problems militating against local production of ceramic products in the country, he said the council had been involved in promoting programmes and projects aimed at encouraging production of high-quality ceramics products locally.

He pointed out that the move was to create awareness and sensitize the public on the critical importance of ceramics’ development to economic and industrial growth, adding an inventory of existing ceramic industries was conducted to obtain information on the status of ceramic products manufacturing in the country.

According to him, the study showed the abysmally low level of production which made the council embark on investment promotion in ceramics products manufacturing, compelling the council to pursue the development, production and establishment of processing plants in some parts of the country.

“The first project was the Pharmaceutical Grade Kaolin Plant at Kankara in Katsina State in 1997, while the second was the Industrial Grade Kaolin Plant located at Gwarzo, Kano State in 1998. Both plants were designed to use wet processing methods for the production of pharmaceutical and industrial grade Kaolin respectively. The equipment fabricated locally were blungers, hydro cyclones, sieves, tanks, filter presses, dryers, hammer mills, floatation machines, etc.

“Likewise, the council collaborated with the Niger State government for the establishment of catalytic model factory at Kagara which was commissioned and the council later divested. Most of the equipment were locally fabricated. The plant has installed capacity of 3000 tonnes a year of processed talc. The council’s initiatives have led to the emergence of other talc processing SMEs within Niger and Kogi states that supply processed talc to user industries. This has led to Nigeria being self-sufficient in technical grade talc, and savings of more than N5 billion annually from importation of technical grade talc,” he said.

The RMRDC boss said the council is at present collaborating with Projects Development Agency (PRODA), Enugu and the Federal Institute of Industrial Research, Oshodi (FIIRO), Lagos, to promote the development of other types of ceramics processing plants for the production of products such as tiles, porcelain, china wares, etc. He pointed out that when completed, the project would increase the range of products locally manufactured.

Ibrahim also said the council was also collaborating with Interlinked Technologies Plc, Lagos, Life-Mac Industries Ltd, Oji River Enugu and Dajo Pottery in Makurdi, Benue State to promote increased capacity utilization of their facilities.

He gave the major areas of the council’s interest as refractory bricks and electrical porcelain insulator production, explaining that feasibility reports had been produced on the projects, adding the council in collaboration with other mandated organizations was also considering involving government banks and other financial institutions to create support fund for the ceramics industries.

The council, Ibrahim also said, collaborated with Ibrahim Badamasi Babangida University, Lapai, about three years ago, to characterize the kaolin, talc and other industrial minerals in Niger and Kogi states, adding the results had been published for investors use.

In addition, the council, according to him, is developing a processing/beneficiation plant for feldspar expected to add value to raw feldspar for different industrial applications.

“In view of the importance of this sector to economic development, foreign exchange generation and provision of employment to our youths, the council has put in place strategies to enhance partnership with ceramics stakeholders in the area of capacity building, public private partnership in setting up of a catalytic factory for ceramic products in Nigeria. In addition, the council is working with the tariff board and other relevant agencies to initiate policies that will enhance development of the ceramic sector. Among the objectives of the policy will be to introduce appropriate incentives to encourage investors in the development of the sector, thereby, encouraging rapid growth, competitiveness and sustenance of the ceramic industries,” he added.